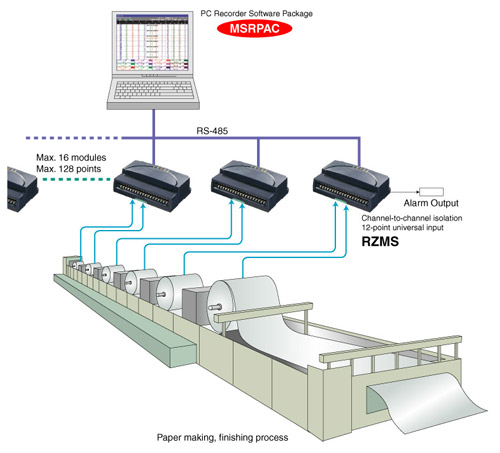

M-System’s

MSR128 series is a Windows PC-based recorder software program, which connects

to economical I/O modules such as models RZUS, RZMS, R1M, R2M, R3 and R5 for DC

mV, mA, Thermocouple, RTD/potentiometer inputs and discrete I/Os. The MSR128 is

fully featured enabling the logging, trending, acquisition and analysis of application

data. Combined with I/O modules, the MSR128 provides a low cost industrial grade

data acquisition system. M-System’s

MSR128 series is a Windows PC-based recorder software program, which connects

to economical I/O modules such as models RZUS, RZMS, R1M, R2M, R3 and R5 for DC

mV, mA, Thermocouple, RTD/potentiometer inputs and discrete I/Os. The MSR128 is

fully featured enabling the logging, trending, acquisition and analysis of application

data. Combined with I/O modules, the MSR128 provides a low cost industrial grade

data acquisition system.

Pulp and Paper Uses:

• Bearing replacement timing forecast.

M-System’s PC Recorder is being used to monitor the temperature of bearings

used in production equipment. Given the process-critical nature of this application,

any bearing failure or unplanned machine downtime is extremely costly. For the

pulp and paper mill, the main benefits of being able to predict bearing replacement

are reduced downtime and quiet line operations at high speed. During normal line

operation, should bearing slippage occur, the lubricant can lose it’s cushioning

effect and the rolling elements, therefore, will come into direct contact with

the raceways. This can lead to bearing damage. Typically, diagnostic equipment

is used to find the problem. However, this is expensive and time consuming to

setup and calibrate before diagnosing the problem. So, using M-System’s MSR128

is a very cost effective solution and can be easily setup by the user. The RZMS

series is equipped with an alarm output (photo MOSFET relay) for visual warnings

to engineering staff.

• Wire saver, communication network.

M-System’s PC Recorder also enables plant side users to reduce the costs

of additional wiring due to the PC Recorder’s ability to communicate over

Modbus RTU.

• Easy system expansion via Modbus RTU

User has the ability to monitor multiple production equipment to allow for easy

comparison and analysis of bearing life as well as other plant functions via multi-drop

or daisy chaining of M-System PC Recorders. |