M-System’s

MSR128/MSRpro series is a Windows PC-based recorder software program,

which connects to economical I/O modules such as models RZUS, RZMS, R1M,

R2M, R3 and R5 having inputs of DC mV, mA, thermocouple, RTD/potentiometer

and discrete I/Os. The MSR128/MSRpro is fully featured, enabling the logging,

trending, acquisition and analysis of application data. Combined with

I/O modules, the MSR128/MSRpro provides a low cost industrial grade data

acquisition system. M-System’s

MSR128/MSRpro series is a Windows PC-based recorder software program,

which connects to economical I/O modules such as models RZUS, RZMS, R1M,

R2M, R3 and R5 having inputs of DC mV, mA, thermocouple, RTD/potentiometer

and discrete I/Os. The MSR128/MSRpro is fully featured, enabling the logging,

trending, acquisition and analysis of application data. Combined with

I/O modules, the MSR128/MSRpro provides a low cost industrial grade data

acquisition system.

M-System’s MSRpro is a ‘paperless pen-type’ recording

system for PC-based data acquisition and analysis, supporting a total

of 2048-channel analog and discrete signals. By communicating with I/O

modules that have a LAN card communication interface, the MSRpro reads

input signals and stores them in a hard disk as digital data. The MSRpro

is a suite of three programs: the MSRpro-Server (referred hereafter as

‘Server’), MSRpro-Builder (‘Builder’), and the MSRpro-Client/Analyzer

(‘Client’).

This software package provides a simple solution while still maintaining

the wide versatility of available types of signal combinations that has

made M-System a vendor of choice in many applications around the world.

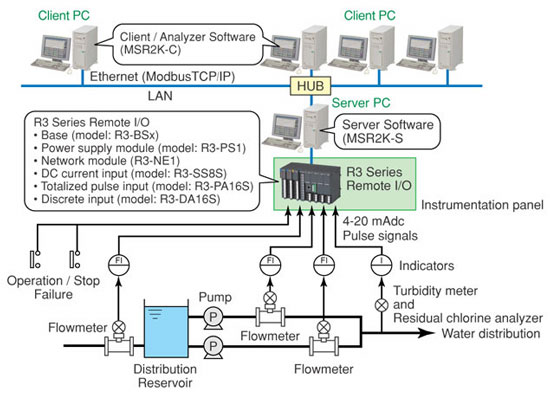

Success Story – Waterworks Department

– Water Distribution Facilities

In this application, the customer did not have any type of recorder, and

was previously logging data by hand. They were looking for a solution

to save man-hours currently spent manually logging data as well as improve

accuracy of data. Measurement signals were for water distribution flow

volume, distributing reservoir water level, chlorine residual level, and

turbidity.

The reasons MSRpro was chosen:

- Real time monitoring is available using a maximum of 4 client PCs.

- Stored data can be saved as a CSV file, which is easily read by popular

spreadsheet software packages such as Microsoft Excel, allowing the

user to take full advantage of spreadsheet software features.

- Various operation functions are available including a calculation

of adding flow signals.

Connecting client PCs over Ethernet to a server PC in the field, a maximum

of 4 client PCs are available for real time monitoring of field sensors.

Converting stored data in the server into a CSV file is available. R3

series’ remote I/O was used to accept field signals. The R3-SS8S,

or DC current input card, was used to input 4-20 mAdc signals from the

flow meters. Under the basic mode setting, input signals are displayed

on the trend view, using a variety of engineering units. When using the

operation function, data undergoing a certain type of operational change

can be plotted.

The R3-PA16S, totalized pulse input card, is used to input pulse signals

from flow meters.

The customer also needed to monitor the pump’s operation/stop, failure

and other functions, so the R3-DA16S discrete input cards were used to

display an alarm view. The alarm history will appear with time stamps

as determined by the builder software for alarm events, start/stop of

pumps and other events. Alarm events are initially shown in red. Under

the heading of Acknowledge, the user is able to click on an appropriate

cell to acknowledge an alarm. Once it is acknowledged, the relevant cell

turns to green.

|