M-System’s MSR128/MSRpro series is a Windows PC-based recorder software program, which connects to economical I/O modules such as models RZUS, RZMS, R1M, R2M, R3 and R5 having inputs of DC mV, mA, thermocouple, RTD/potentiometer and discrete I/Os. The MSR128/MSRpro is fully featured, enabling the logging, trending, acquisition and analysis of application data. Combined with I/O modules, the MSR128/MSRpro provides a low cost industrial grade data acquisition system. M-System’s MSR128/MSRpro series is a Windows PC-based recorder software program, which connects to economical I/O modules such as models RZUS, RZMS, R1M, R2M, R3 and R5 having inputs of DC mV, mA, thermocouple, RTD/potentiometer and discrete I/Os. The MSR128/MSRpro is fully featured, enabling the logging, trending, acquisition and analysis of application data. Combined with I/O modules, the MSR128/MSRpro provides a low cost industrial grade data acquisition system.

M-System’s MSRpro is a ‘paperless pen-type’ recording system for PC-based data acquisition and analysis, supporting a total of 2048-channel analog and discrete signals. By communicating with I/O modules that have a LAN card communication interface, the MSRpro reads input signals and stores them in a hard disk as digital data. The MSRpro is a suite of three programs: the MSRpro-Server (referred hereafter as ‘Server’), MSRpro-Builder (‘Builder’), and the MSRpro-Client/Analyzer (‘Client’).

This software package provides a simple solution while still maintaining the wide versatility of available types of signal combinations that has made M-System a vendor of choice in many applications around the world.

|

| Figure 1. MSRpro. |

Success Story — AC current monitoring at hospital’s surgical facility

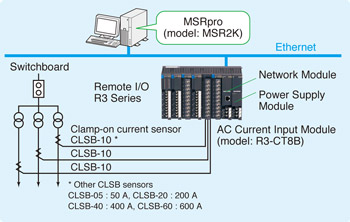

In this application, the customer is using MSRpro (Model MSR2K) for the monitoring of AC current at their hospital’s surgical facility. There are various medical equipment in the surgical facility, many of which consume high amounts of AC current. Approximately 50 pieces of equipment are used in the surgical facility, and their current consumption changes depending on the type of surgery and if it’s used for surgery or not. The customer wanted to know how much current each piece of equipment consumed, according to individual systems, and total current consumption of the entire surgical facility. Then they wanted to use those results to reduce energy consumption in the facility.

|

| Figure 2. System configuration. |

The customer wanted the measurement device to be able to move around the surgical facilities and collect certain periodical data. For that purpose, a R3-CT8B with the clamp-on current sensor CLSB-10, 0 to 100A, was selected. The R3 series is compact in design, with the base dimension of a single R3-BS10 with 10 I/O positions measuring only W280 x H135 mm. Per Figure 1 and 2, it is used together with a PC and R3 series modules brought into each surgical facility.

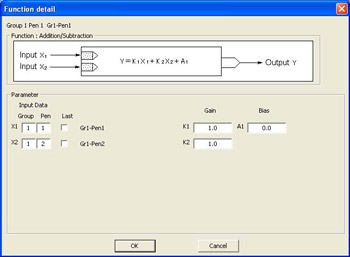

The reason MSRpro was selected was not only for measuring each surgical device’s current consumption but also to measure total current consumption of an entire surgical facility. The MSRpro has math functions, and using the trend view function it is able to show total current consumption and each surgical device’s current consumption. Figure 3 shows an example of the Addition function.

|

| Figure 3. Function setting. |

Previously recorded data may be retrieved to show the chart by selecting date and time. Data can be exported to a CSV file, which is read by popular spreadsheet software packages such as Microsoft Excel. The customer liked that MSRpro analyzed Excel data and was able to be used in a presentation at an academic conference.

After the adoption of MSRpro, it was found that the current consumption of lighting in the ward was larger than the current consumption of surgical devices. By adopting the rule of turning off half the lights when the surgical facility was not in use, a significant savings in electricity expenditures was achieved. |