| Multi Power Input Module R3-WTU |

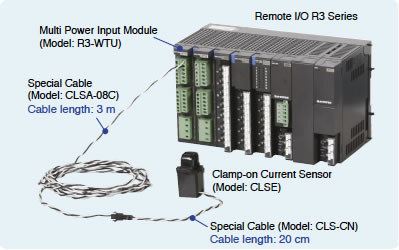

M-System’s R3 Series Remote I/O is designed to support DCS/PLC systems by expanding their I/O flexibility and capabilities. 1. Overview The R3-WTU may also be used to measure additional variables such as current, voltage, demand, and harmonics that supplement existing R3 series power input modules such as the R3-WT1, R3-WT1A, and R3-WT1B. The R3-WTU also provides the user with an easier way to collect more detailed data. 2. Features (2) Connection Methods (3) Measured Variables

M-System’s PC Configurator software (model: R3CON)* is used to configure unit settings such as measured variables, input connections, and sensor types. For each selected measured value, specify 1 word (16 bits) or 2 words (32 bits) and a maximum of 16 words of data for each slot (unit) will be transmitted. Since circuits are selected for individual measured values, the user may combine them freely as long as the data is 16 words or less. For example, the No. 1 circuit can use one word measuring only energy, while the No. 2 circuit uses 15 words for variables such as current, power factor, power, reactive power, and frequency. (4) Scaling (5) Clamp-on Current Sensor (model: CLSE)

(6) Related products M-System also provides a variety of communications cards that can be combined to facilitate power monitoring from a remote computer or PLC. * PC Configurator software is available for download from M-System’s website (https://www.m-system.co.jp/). A dedicated PC Configurator cable (model: MCN-CON or COP-US [USB] ) is required to connect Remote I/O R3 Series units to a computer. |

|||||||||||||||||||||||||||||||||||||||

| Analog Backup Station with Bargraph/Digital Indicator (Model: ABF3) |

|||||||||||||||||||||||||||||||||||||||

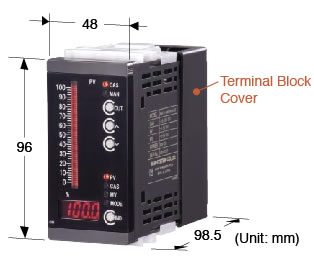

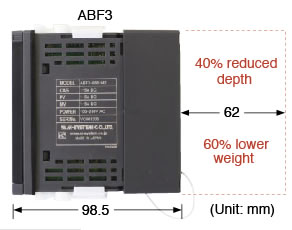

M-System’s Analog Backup Station (model: ABF2) has been well received by our customers over many years. We have developed a new product based on the successful design of the ABF2 and have incorporated a number of suggestions from customers, including a more compact design, waterproof construction, and a more visible bargraph display. In developing the ABF3, we focused on the following three items to improve upon from the ABF2 features:

Easier to operate housing design The most striking difference from the ABF2 is the ABF3’s reduced depth. The newly designed unit is approximately 40% shorter than the ABF2, enabling its integration into shallow control panels. It is also approximately 60% lighter than its predecessor (see Figure 2). A two-piece terminal block design delivers exceptional ease of maintenance and enables the unit to be removed without disconnecting wires from the terminal block. The ABF3 comes with a standard terminal block cover to guards against electric shock, ensuring that work inside the panel can be performed safely. IP65-equivalent degree of protection When installed in a panel cut to dimensions specified by M-System, the ABF3’s front panel offers IP65 protection (this level of protection is not supported for multiple-unit installations).

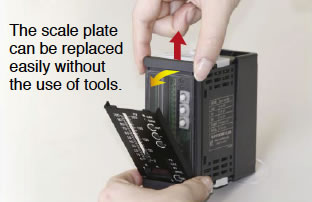

Bargraph display with improved visibility Easy scale plate replacement Since it is no longer necessary to remove any parts other than the scale plate itself, users no longer need to worry about misplacing parts during the scale plate replacement process. |

|||||||||||||||||||||||||||||||||||||||

| KOREA M-CLUB 2008 in Seoul | ||||||||||||||||||

M-System’s annual KOREA M-CLUB meeting was held on the 18th of April in Seoul, Korea. The program for the meeting included the following sessions:

Participants were 7 representatives of distributors and 4 M-System members.

Conference started from the sales report. We reviewed the sales figure, the hit products, and fast growing industries & customers, especially in Korean market. Presentations of products targeted including the Intrinsically Safe & Explosion-proof modules (B6U, 27HU-B etc,.), Ultra-Slim Signal Transmitter M6D series, Paperless Recorder 73VR series. The newly or recently released products, which emphasized this year were Multi Power Monitor 53U&54U, Head Mount Temperature Transmitter 27 series and Digital Panel Meter 47 series. Those products have been bringing additional sales from existing customers. Then, Mr. Kim from IT Company and Mr. Lee from Goodwell made the special presentations this year.

We have been having the KOREA M-CLUB meetings for four consecutive years. M-CLUB surely contributes to build up further business relationship and better understandings of M-System. At the end, we all look forward to seeing next M-CLUB again. |

||||||||||||||||||

| Kim Youngwook – M-System Co., Ltd. (kim@m-system.co.jp) |

||||||||||||||||||

|

||||||||||||||||||

| "Product Training 2008" for Distributors in Southeast Asia | ||||||||||||||||||

With the warm welcome of cherry in full bloom, “Product Training 2008” was held at M-System Headquarters and Kansai Branch in Osaka, Japan from 10th to 12th April 2008. 4 representatives from 4 companies participated in the session this time. The training was started with the factory tour. The attendees learnt how the products that they sell in their daily activities are manufactured and how our quality control is carried out. In the training, we focused on the new & upgraded products such as 53U, 27 series, M6 series, 73VR1100/2100/3100 series, R7 series, MD7 series etc. and some unique function products. The demonstration units were prepared for all featured products and they allowed the attendees to have some ideas of each product.

The attendees shared their success stories, unique applications and problems faced by end users in their countries. The information will help all the attendees to prepare themselves for the future jobs. Just after the training session, one of the attendees managed to convince the customer to have the monitoring system with R3 and MSRpro. We are very happy to see the result so soon. We will organize more of these sessions. We are looking forward to seeing all of you in the session in the near future. |

||||||||||||||||||

| Kay Yasumaru – M-System Co., Ltd. (yasumaru@m-system.co.jp) |

||||||||||||||||||

Report 1 The factory tour on the first day of our training agenda gave us the insight of operation of each department and the production processes. The training sessions conducted by the experts from various product lines; coupled with the opportunity to interact with the experts face to face on questions and answers; and also the live demo of the products with the demo kits, all these gave us a very in- depth understanding of the product’s functionality and capability. After two days of hard work; a sightseeing program was organized for all the attendees to visit the beautiful ancient capital of Japan-Kyoto. It was a wonderful experience being present yourself at the real scene of “Kiyomizu-dera (Buddhist temple)”, and “Kinkaku-ji (Golden temple)”; which we have seen their photos very often being printed on the calendars and magazines. My heartfelt thanks to Kay san for accompanied us for the entire event; for taking care of all our meals, transportation and accommodation; and being our mentor and interpreter during the training sessions; and also acts as our tour guide during our visit to Kyoto. I also wish to thanks Noda san for his lively demo on the signal transmitters and surge arresters, and also not forgetting Nakaya san and Ami san who work behind the scene to make this a successful event. |

||||||||||||||||||

| K M Tan – Roswell Pte Ltd. (km.tan@roswellpteltd.com.sg) |

||||||||||||||||||

Report 2 During this two-day training, I have learnt a lot from the many experience M-System employees. The training is conducted with many software demo as well as product demonstration. It is a very good training method and of course easier to understand. The factory tour gives us an idea on how M-System product is being made from PCB to become finish products. I was impressed with the manufacturing technology and also the quality control system in M-System factory. This is the first time for me visiting Japan. All the employees of M-System are very friendly and polite. This gives a very warm feeling to me because I feel very much am at home. |

||||||||||||||||||

| Voon Chee Hoong – Wehaya Regelung Sdn Bhd. (voonch@wehaya-regelung.com.my) |

||||||||||||||||||

Report 3 The most important, from the M-System product training, I have learnt a lot about the product detail and information. Both items that I have sold before and new products such as Remote I/O, PC Recorder, Lightning Surge Arresters, Functional Transmitter, Two-wire Products, M6D Series, FOUNDATION Fieldbus, Multi Power Monitor and it seemed everyone enjoyed the training both technical and practical. The M-System trainers have also taught me about product’s technical and sales strategy, which I think it, would improve me from ordinary sale person to the super-sale!!! I would like to take this opportunity to thanks all M-System staffs for being a good company since stepped down off from air plane to hotel and all good meals provided, factory tour, excellent sightseeing until I came back home safe and sound. |

||||||||||||||||||

| Waranya Supamith – Petro-Instruments Corp., Ltd. (waranya@pico.co.th) |

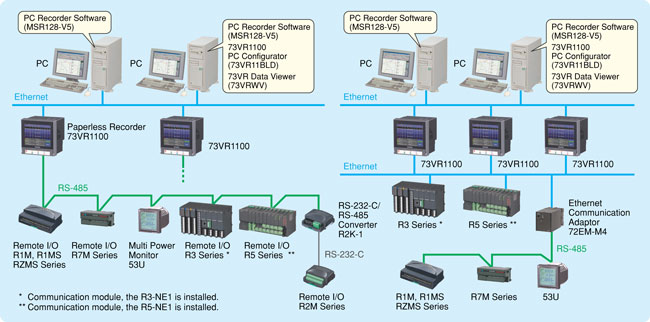

| Model 73VR1100, Paperless Recorder | ||

The 73VR1100 is paperless recorder, which is designed to utilize a wide variety of M-System’s remote I/O devices R1, R3, R5 and R7 series as well as multi power monitor 53U. The remote I/O devices can be connected each other via RS-485, twisted pair cable. The 73VR1100 saves data to the inserted CF card. You can monitor each input pen data on the 5.5-inch TFT LCD. Online real time monitoring is also available at a PC via Ethernet connection. The 73VR1100 is panel flush mountable and the front panel protection level is IP65. |

||

|

||

Figure 1. System configuration examples |

||

| Zero-phase Current Transmitter Input, Model KCEZ | ||

|

Offices & Factory Closed The operation and hotline support group will go to Ehime for overnight trip. We will cruise round Seto Inland Sea and enjoy the Dogo hot springs, the oldest one in Japan. For M-System staff, the trip will be a golden opportunity to foster closer relationships each other.

|

|

CLIPBOARD is a newsletter from M-System. Introducing new products, product literature and other important information we pick up in our daily business correspondence. Your comments, views and contribution are especially welcome. |

| International Sales Department Tel: +81-6/6659-8201 Fax: +81-6/6659-8510 Mail:info@m-system.co.jp |

| Copyright (C) 2008 M-System Co., Ltd. All rights reserved. |