M-System’s

MSRpro is a ‘paperless pen-type’ recording system for PC-based

data acquisition and analysis, supporting a total of 2048-channel analog

and discrete signals. By employing the R3 Series Remote I/O as an input

device, a wide variety of field sensor signals including temperature,

DC and AC, relays and open collectors can be handled. In addition, various

math and filter functions can be applied to the input signals in order

to maximize the benefit of the expanded analytical functions of MSRpro.

Utilizing just one PC, which can run both the Server and the Client, up

to 512 points can be monitored. The Server and Client should be installed

on independent PCs for additional input signals. Four Client PCs can access

the Server with up to 8 field stations able to be connected. The MSRpro,

model MSR2K, is a suite of three programs: the MSRpro-Server (referred

hereafter as ‘Server’), MSRproBuilder (‘Builder’),

and the MSRpro-Client/Analyzer (‘Client’). This software package

provides a simple solution while still maintaining the wide versatility

of available types of signal combinations that has made M-System a vendor

of choice in many applications around the world. M-System’s

MSRpro is a ‘paperless pen-type’ recording system for PC-based

data acquisition and analysis, supporting a total of 2048-channel analog

and discrete signals. By employing the R3 Series Remote I/O as an input

device, a wide variety of field sensor signals including temperature,

DC and AC, relays and open collectors can be handled. In addition, various

math and filter functions can be applied to the input signals in order

to maximize the benefit of the expanded analytical functions of MSRpro.

Utilizing just one PC, which can run both the Server and the Client, up

to 512 points can be monitored. The Server and Client should be installed

on independent PCs for additional input signals. Four Client PCs can access

the Server with up to 8 field stations able to be connected. The MSRpro,

model MSR2K, is a suite of three programs: the MSRpro-Server (referred

hereafter as ‘Server’), MSRproBuilder (‘Builder’),

and the MSRpro-Client/Analyzer (‘Client’). This software package

provides a simple solution while still maintaining the wide versatility

of available types of signal combinations that has made M-System a vendor

of choice in many applications around the world.

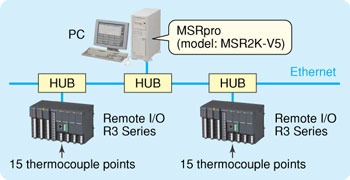

Success Story - Temperature monitoring at a

synthetic fiber plant

The customer was looking for a solution to replace paper chart recorders,

which were being used to monitoring temperature at their synthetic fiber

plant.

One of the processes at the plant is designed to make otherwise useless

non-standard products that are generated during the synthetic fiber manufacturing

process into chips to facilitate their reuse. During this process, newly

made chips are dried with a hot air drier called a power drier. The monitoring

of the temperature of this piece of equipment was the reason that the

PC recorder was selected.

|

| Figure1. System Configuration |

Previously the customer had been using a paper chart recorder to monitor

over 30 points of temperature data. Many years had passed since the customer

had installed the original paper recorder, and the customer was considering

a replacement. Initially the customer was considering the replacement

of an identical paper chart recorder since they had experience using it

and were familiar with its operation. However, the high cost of doing

so, coupled with the need for maintenance when the unit experienced a

paper jam or ran out of paper ultimately led the customer to opt for a

maintenance-free PC recorder, and they chose M-System’s MSRpro.

The most significant factor in their decision was that the M-System configuration

could be easily built and at a low cost. The customer was able to achieve

dramatic cost savings compared to a chart-type recorder by using R3 Series

remote I/O units.

| Table 1. Setting Accessible to General Users |

| Setting category |

Configurable parameters |

PEN Configuration

|

Show/Hide, Thick line, Plot position, Logarithm settings |

| ALARM Configuration |

All |

| TREND Configuration |

Pen panel percent (Perpendicular / Horizontal), Connected |

| ACTIVE TREND Configuration |

Pen panel percent (Perpendicular / Horizontal) |

| OVERVIEW Configuration |

Group alarm indicator, Connected |

| ANALYZER Configuration |

Graph brightness |

| SAVE & READ Configuration |

All |

| Save Configuration in CSV |

All |

Another point in the MSRpro’s favor was the ability for users to

configure their own settings. It would be extremely expensive to operate

the system if adding data display points or changing the display method

or range necessitated calling in a representative from the software manufacturer.

By contrast, the customer appreciated the fact that MSRpro makes it easy

for users to change their own settings since it does not use a special

language to control the manipulation of settings.

The MSRpro’s password function was another factor in the customer’s

decision. Although the ability for users to change their own settings

is an advantage, allowing floor workers who are not specialists access

to settings screens can be problematic in some cases.

The accessibility of MSRpro and its functions can be determined on a

worker-by-worker basis by using the password function, which allows accessibility

to be apportioned between workers who can access all operations (all setting

changes) and workers who can change only settings such as display and

alarm functionality that do not affect critical areas of system operation

(This operation is not available when the server is not operating.) (see

Table 1). Finally, the application of password restrictions enables users

to avoid device down time caused by improper operation.

The customer chose MSRpro PC recorder software (MSR2K-V5) as a result

of the features described above, and they remain very satisfied with their

choice. |