What is a Strain Gauge Load Cell?

Principles of strain gauge load cells

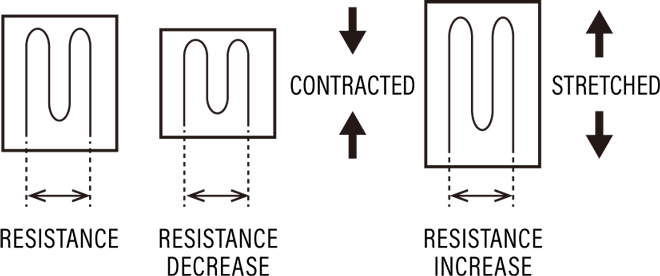

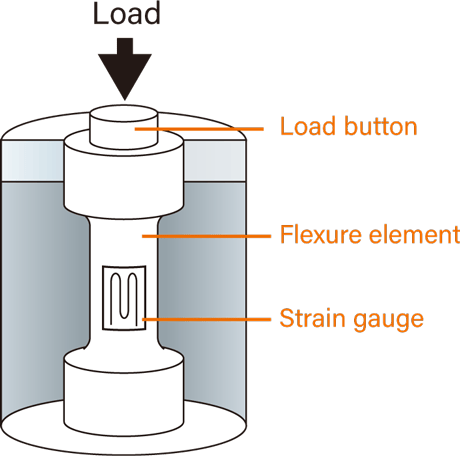

A strain gauge load cell consists of a combination of a metal that deforms when a force is applied, and a sensor whose resistance changes when it deforms. Metals that deform when a force is applied are called flexure elements, while sensors whose resistance changes when they deform are called strain gauges. A strain gauge exhibits the following characteristics with respect to deformation.

Wheatstone bridge circuit and rated output

The resistance change in a strain gauge is so small that it is converted to a voltage using a Wheatstone bridge circuit.

When the resistance values of R1 × R3 and R2 × R4 are equal, the output voltage of the Wheatstone bridge circuit is 0 V. When the resistance values are not equal, the output voltage changes accordingly. The rated output values in the matrix table represent the output voltages for an excitation voltage of 1 V when the strain gauge load cell is subjected to a force of the rated capacity.

represent the output voltages for an excitation voltage of 1 V when the strain gauge load cell is subjected to a force of the rated capacity.

Types of strain gauge load cells

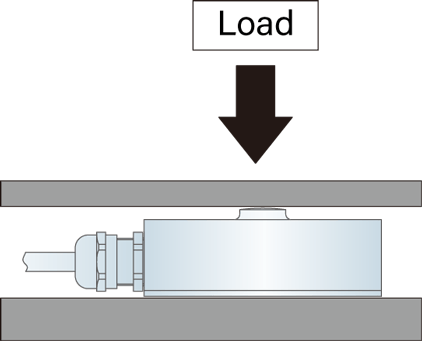

Compression Type

The most common type of strain gauge load cells. Available in various capacities and sizes.

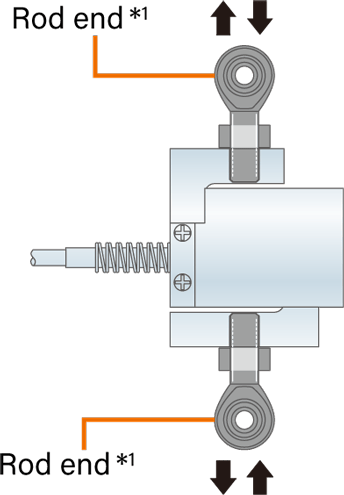

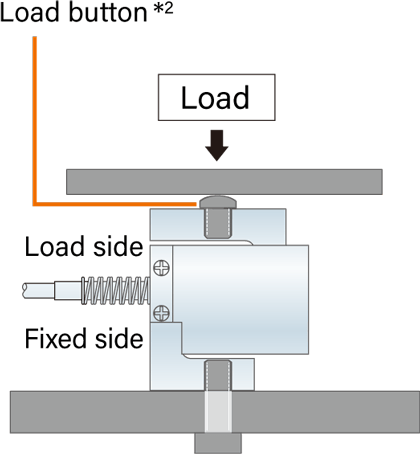

Tension/Compression Type

Used by connecting rod ends*1 or eyebolts at the top and bottom. When used for compression, care must be taken because there are two sides, the fixed side and the load side.

Rod end: A type of bearing consisting of a spherical ball enclosed within a housing. This construction allows for complex movement.

*1. Prepared by user

*2. Consult us for more information.

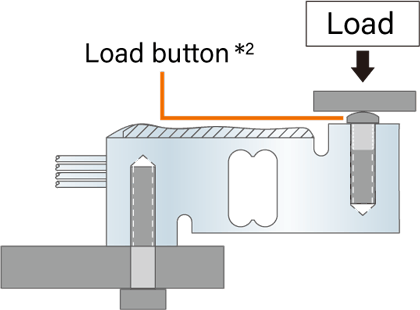

Beam Type

The beam type is used when the strain gauge load cell extends from the frame or housing. Typically, a set of three to four beams is used for weighing or the like.

*2. Consult us for more information.

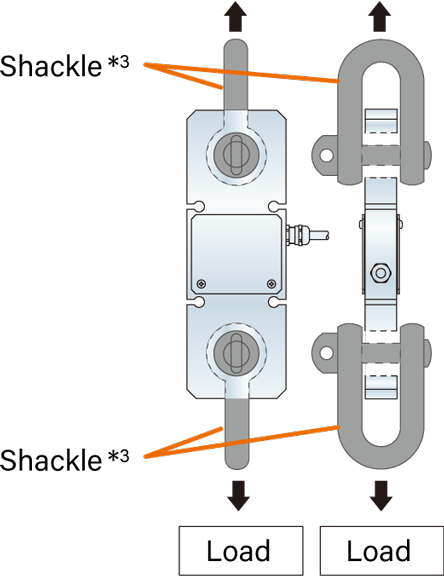

Tension Type

Strain gauge load cells for cranes. Used by connecting shackles*3 or the like.

Shackle: A metal fitting used to connect a wire rope or a sling with a load.

*3. Prepared by user